RFID Equipment Introduction

RFID Equipment Introduction

RFID Equipment Introduction

RFID Equipment Introduction

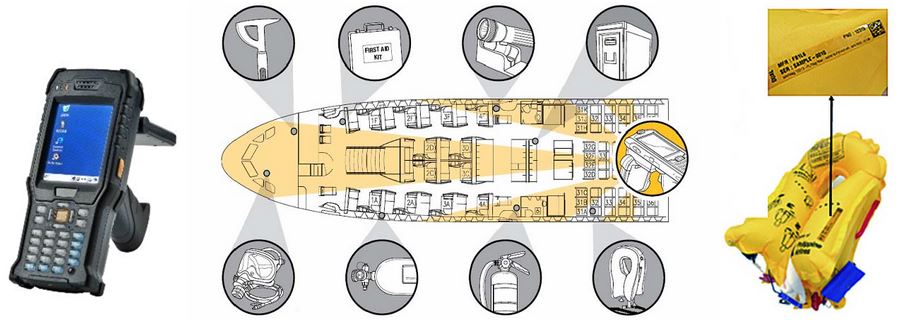

The aviation RFID products independently developed by Guangzhou Allin meet the requirements of Boeing and Airbus, and obtained full EASA DOA approval in August 2015. They can be used for rapid detection of life-limited parts such as life vests and oxygen generators, as well as for LRU component testing, warehouse management, tool management, etc.

Airbus and Boeing have issued documents requiring that LRU components produced by OEMs and parts repaired by MROs in the future must be labeled with RFID tags when leaving the factory, so that airlines can quickly read all previous fault record information using RFID when troubleshooting problems during future use.

Airbus began installing RFID tags on all life vests for A320, A330, and A380 models leaving the factory in 2013. Starting in 2015, Airbus installed RFID tags on all life vests for A350 models leaving the factory. They also require all approved BFE seat manufacturers to install anti-metal RFID tags on all seats delivered to Airbus assembly lines.

Therefore, based on the above, the use and promotion of RFID will become a trend! Guangzhou Allin sincerely hopes that the use of RFID can reduce workload, improve work efficiency, and save costs for airlines!